Chapter 19 in Composites Assembly for High Performance Fastener-less Structures, 2022, ISBN-13: 978-1-83953-149-1

Frequently, the technical standards for the properties of materials to be utilised in products surpass the capabilities of a single material class, such as polymers, metals or ceramics. Such limits may sometimes be circumvented by mixing two types of materials in a single product, i.e., by creating a composite. In such composites, one of the two material classes oversees supplying one set of desired features, while the other material is in charge of giving a separate set of desirable (but related) traits.

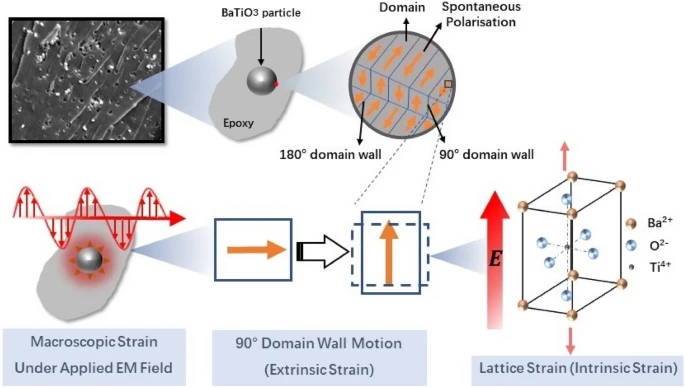

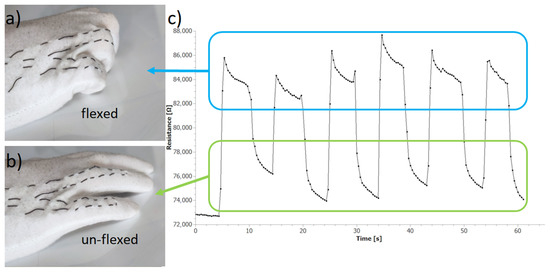

Because of their combination of high strength, high stiffness and low density, advanced polymer composite materials are gaining popularity for applications need high strength, stiffness and low density, such as automobile and aerospace industries. While the main role of these composites has historically been to support certain loads, there is a rising tendency in research to include various secondary functions into composite structures. There is a growing need for materials that combine required functional qualities like load sensing, energy harvesting, temperature monitoring, actuation, etc. with mechanical performance. Moreover, aviation safety standards and assuring structural integrity dependability are critical elements that drive the usage of such materials in aircraft structures. To meet both requirements, non-destructive inspection of the structure is performed, which is more difficult and expensive than inspecting metallic structures. As a result, new in situ health monitoring approaches must be developed.

In the quest to decrease maintenance costs, remote monitoring of components in systems and structures has become vital. Typically, a health monitoring module with a sensor, wireless telemetry and processing capacity is spread across complicated structures and must function remotely utilising battery power. A battery can only provide power for a certain amount of time before it must be recharged or replaced, resulting in a cost of maintenance. A wireless data transmission module, sensors and an energy harvesting device are often included in a self-powered health monitoring module. Systems have been extensively researched to convert energy from widely accessible sources such as vibration, human motion, water, air, heat, light and chemical processes into usable electrical energy.

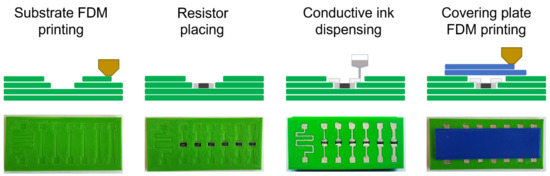

In this chapter, we briefly describe energy harvesting and self-sensing polymer composites.