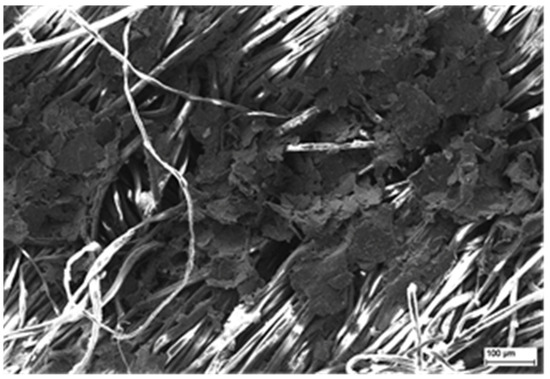

Due to the appearance of smart textiles and wearable electronics, the need for electro-conductive textiles and electro-conductive paths on textiles has become clear. In this article the results of a test of developed textile electro-conductive paths obtained by applying the method of screen printing pastes containing silver nanoparticles and carbon (graphene, nanotubes, graphite) are presented. Conducted research included analysis of the adhesion test, as well as evaluation of the surface resistance before and after the washing and bending cycles. Obtained results indicated that the samples with the content of carbon nanotubes 3% by weight in PMMA on substrate made of aramid fibers (surface mass of 260 g/m2) were characterized by the best adhesion and the best resistance to washing and bending cycles. Such electro-conductive paths have potential to be used in smart clothing applications.